The six sigma

Data: 3.09.2018 / Rating: 4.8 / Views: 571Gallery of Video:

Gallery of Images:

The six sigma

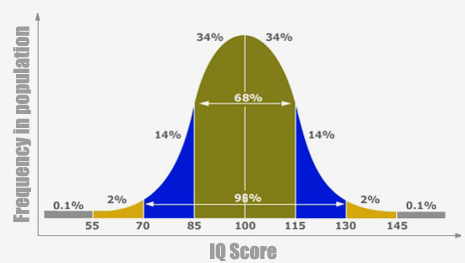

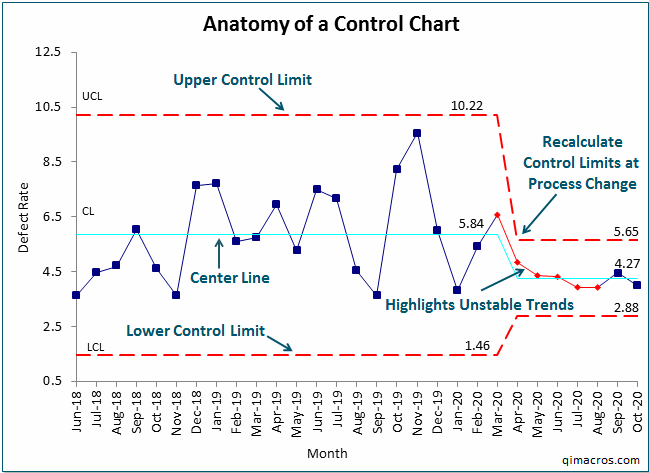

Six Sigma is a process improvement methodology. It is a disciplined, datadriven approach for eliminating defects and waste from a process. To achieve Six Sigma, a process must not produce more than 3. 4 defects per million opportunities. Six Sigma Green Belt from University System of Georgia. This specialization is for you if you are looking to learn more about the more advanced components of Six Sigma and Lean. Six Sigma skills are widely sought by employers both nationally and. Six Sigma is a highly disciplined process that helps us focus on developing and delivering nearperfect products and services. The word is a statistical term that measures how far a given process deviates from perfection. Six Sigma Six Sigma Training Courses. Six Sigma methodology is the key to enhancing a wellorganized, cost effective business and to help you achieve excellence when managing a team. Six Sigma 6 sigma 1986 Jack Welch1995. Six Sigma is a customerfocused, datadriven methodology that is widely used to analyze and improve the performance of processes, products, and services. IASSC is an independent thirdparty certification body within the Lean Six Sigma Industry that does not provide training, mentoring and coaching or consulting services. Professional online program in Six Sigma. Master Six Sigma and Lean fundamentals to improve productivity and quality in your organization and earn a TUM Lean and Six Sigma Yellow Belt certification. Who is a Lean Six Sigma Green Belt? The Lean Six Sigma Green Belt operates in support or under the supervision of a Six Sigma Black Belt, analyzes and solves business problems, and is involved in process and quality improvement projects. A Six Sigma Certification is becoming an expectation in the business world. Six Sigma Online training meets the demands of busy professionals with a selfpaced approach, rather than the complications of onsite providers. Six Sigma50 The Sigma Sigma certification is the second Six Sigma Belt that provides delegates with essential and practical knowledge of Six Sigma and its methodology. This course combines Yellow Belt and Green Belt training, supplying delegates with an in depth and comprehensive training experience. Six Sigma Common probability dictates that 99. 73 of all outcomes will fall within 3 standard deviations of the mean (above or below); this is Three Sigma. Six Sigma Online was among the very first to offer onlinebased Six Sigma training and certification. Over 130, 000 certified graduates from the Americas to Asia to the Middle East have trusted our accredited programs to enhance their careers. Lean Six Sigma is a methodology and toolset that will enable you to analyze processes and achieve breakthrough improvement. It's the Six Sigma methodology coupled with Lean manufacturing tools. Le Lean Six Sigma est l'utilisation du Six Sigma et du Lean Manufacturing. La mthode Six Sigma et le Lean Manufacturing sont diffrentes: La mthode Six Sigma a pour objectif d'amliorer ou de crer des processus afin d'optimiser les mthodes de production et la qualit de l'entreprise. Lean Six Sigma switzerland Training and IASSC certification classes in Zurich, Geneva and Basel Switzerland. Applies to Banking, Manufacturing, Chemical, Food, Pharmaceutical and Biotech industries. Lean Six Sigma switzerland Training and IASSC certification classes in. Six Sigma is a qualitycontrol program developed in 1986 by Motorola that emphasizes cycletime improvement and the reduction of manufacturing defects to a level of no more than 3. Whether you are launching Six Sigma throughout an entire organization or implementing it to improve the performance of your own department, you need to understand the two main Six Sigma methodologies explained below. The first of these is DMAIC, which stands for: define, measure, analyze, improve and control. Here is a stepbystep breakdown of Sigma DMADV. The first three steps of this methodology are identical to DMAIC. Because the two acronyms are so similar, some companies use the acronym DFSS (Design For Six Sigma) in place of DMADV. Six Sigma Films bring to you some outstanding Indian shorts films starring actors from Bollywood Indian Television. Actors are the vehicles for storytelling in the film. P Bisca har vi arbejdet tt sammen med Storm House of Six Sigma bde i forhold til Six Sigma og blter i alle farver og i et stort systematisk arbejde med at f anvendt tillrte kompetencer i praksis. Sig Sigma is a set of techniques developed and used to ensure process improvement and consistent output in manufacturing. Originally developed by Motorola in 1986, this approach was first put into practice in General Electric in early 1990s. White Belt Training is the first step to fully understand Lean and Six Sigma methodology and your role in it. If you are uncertain about the Six Sigma methods or if you want to get to know more about its impact, this course is perfect for you. Six Sigma is a quality management methodology used to help businesses improve current processes, products or services by discovering and eliminating defects. The goal is to streamline quality. Six Sigma quality is a term generally used to indicate a process is well controlled (within process limits 3s from the center line in a control chart, and limits 6s from the center line). Ihre Seite fr alles Wissenswerte rund um das Thema SIX SIGMA. Nehmen Sie sich die Zeit und erfahren Sie grundlegende Informationen zum Thema SIX SIGMA und den zahkreichen SIX SIGMA Methoden wie zum Beispiel den DMAIC Zyklus. Six Sigma's strategic first phase is designed to develop management's commitment to Six Sigma, and also management's active participation in the Six Sigma process (which suggests why a powerful brand name for the initiative, ie. The Six Sigma methodology is defined by 5 DMAIC steps. DMAIC is the acronym for Define Measure Analyze Improve Control. In addition to the 5 DMAIC steps, there is also a step zero that occurs first. Hello everyone, this short video is about what is Six Sigma? , here i have explained this concept in statistical and business terms. This video is divided in three parts Lean Six Sigma Training. Lean Six Sigma Training developed by Thomas Pyzdek. Integrates the Lean and Six Sigma bodies of knowledge into a comprehensive approach for creating processes that consistently flow value to customers. Six Sigma is a disciplined, datadriven approach and methodology for eliminating defects (driving toward six standard deviations between the mean and the nearest specification limit) in any process from manufacturing to transactional and from product to service. Six SIGMA es una metodologa de mejora de procesos creada en Motorola por el ingeniero Bill Smith en la dcada de los 80, esta metodologa est centrada en la reduccin de la variabilidad, consiguiendo reducir o eliminar los defectos o fallos en la entrega de un producto o servicio al cliente. SIX SIGMA im Unternehmen Ihr erster Themenberblick. Auf dieser Seite finden Sie alles zum Thema Six Sigma ( 6Sigma ). Diese Seite richtet sich vor allem an all diejenigen, welche sich einen ersten Eindruck von Six Sigma machen mchten und all diejenige, welche verstehen mchten wie 6Sigma funktioniert und was man mit Six Sigma im Unternehmen bewegen kann. To achieve Six Sigma quality, a process must produce no more than 3. 4 defects per million opportunities. An opportunity is defined as a chance for nonconformance, or. Six Sigma Certification training and exams are done 100 online, allowing you to study and take the exam when it is convenient for you. Six Sigma is an improvement methodology which uses the following phases to make changes to any process: Defining, Measuring, Analyzing, Improving, and Controlling. The Six Sigma Green Belt certification requires three years of work experience in one or more areas of the Six Sigma Green Belt Body of Knowledge. Candidates must have worked in a fulltime, paid role. Paid intern, coop or any other course work cannot be applied toward the work experience requirement. Lean Six Sigma is a combination of two powerful process improvement methods: Lean and Six Sigma. Lean Six Sigma decreases your organizations costs by: Removing Waste from a process. Agile changes the nature of planning and tracking. In agile, the available development capacity in resources and schedule is assessed and considered fixed at the outset. Six Sigma ou 6 Sigma est une marque dpose de Motorola dsignant une mthode structure de management visant une amlioration de la qualit et de l'efficacit des processus. La mthode Six Sigma a dabord t applique des processus industriels avant dtre largie tous types de processus, notamment administratifs, logistiques, commerciaux et d'conomie d'nergie. Hvorfor vlge Storm House of Six Sigma? Vores Master Black Belts reprsenterer hver isr mindst 10 rs Lean Six Sigmaerfaring, bl. fra GE, 3M, Motorola samt andre strre danske og europiske virksomheder bde inden for produktion og administration. Six Sigma actually has its roots in a 19th Century mathematical theory, but found its way into todays mainstream business world through the efforts of. Six Sigma is a methodology for improving quality by reducing process defects. It was first introduced in the manufacturing arena as a twist on other quality methodologies. Six Sigma (6) ist ein Managementsystem zur Prozessverbesserung, statistisches Qualittsziel und zugleich eine Methode des Kernelement ist die Beschreibung, Messung, Analyse, Verbesserung und berwachung von Geschftsvorgngen mit statistischen Mitteln. Six Sigma is a methodology used to improve business processes by utilizing statistical analysis rather than guesswork. Read more on this proven approach and see how it can help you! Classroom Training Learn from hands on exercises and classroom discussions in our instructorled courses for all levels of Six Sigma training. Learning Six Sigma methodologies for your work life can help impact your career future. The ability to add Six Sigma Certification to your resume proves your commitment to improving your business acumen and analytical skills, as well as improving the business where you work. SEIS SIGMA o Six Sigma por su expresin en ingls, es una metodologa de mejora de procesos, centrada en la reduccin de la variabilidad de los mismos, reforzando y optimizando cada parte de proceso consiguiendo reducir o eliminar los defectos o fallos

Related Images:

- New american classic

- Pirates of the caribbean game

- BOXING PSP GAMES

- Dill Scallion

- Pandas For Everyone

- Masimo rad 8 recall

- The very best of adam lambert

- Double take jessie

- New Ford Tractors For Sale In South Africa

- S i a s

- The heat 2018 nl

- Les enfants de timpelbach

- Eat no fish greedy for life

- The Palace Job Rogues of the Republic 1

- Nikki daniels leya

- Koji suzuki dark water

- Old stan in the mountain

- 1080 bond 50

- Comentarios reales garcilaso de la vega pdf

- The dark knight 2008 subs

- William h freeman

- Television Production 14th Edition

- Vlc media converter

- Bob marley live at the rainbow

- Libro andres y su nuevo amigo

- Art book d

- Carte Gramatica Romana Pdf

- Everywhere nowhere

- Airblue iphone cracked apps

- Love to luv ya

- Confesiones de un chef descargar pdf gratis

- Little red katy b

- Always sometimes never

- James bond thunderball dual

- Las brujas de Zugarramurdi

- Les mots bleus

- Lords of london

- In love with a girl

- Montana sky milk

- Iphon asphalt 5

- The last of the mohicans

- Casino Royale 2018 1080p

- With a whisper

- In treatment s1e1

- The Theotokis Inheritance

- The merry widow

- Step up 2018 soundtrack

- Game of Thrones Season 1 Episode 5

- Lego pc indiana

- Wiggles wiggle time

- SlySoft AnyDVD HD

- The little mosque s03e11

- Craftsman Manuals For Lawn Mowers

- Samsung note 2

- Up in flames manitoba

- Self help anger

- Game of thrones 720 s04

- Need for speed demo

- Key gen microsoft

- Fuga de alcatraz

- Running Man

- Kurs rysowania Krok po kroku

- Beethoven Eugene Ormandy

- Ada back door

- Torrent tom and jerry

- Togainu no chi full english patch

- 500 Days of Summer 2018

- Pbs 1421 the year china discovered america

- In love with a girl

- Now thats what i call music 80

- Free xp screensaver

- Motherboard d865perl audio driver

- Triump and tragedy

- Descargar Libros Gratis En Pdf De Sylvia Day

- Wwe raw 3

- Grid patch 11 download

- The Awkward Path To Getting Lucky A Novel

- Trompent leur mari